Your shopping cart is empty!

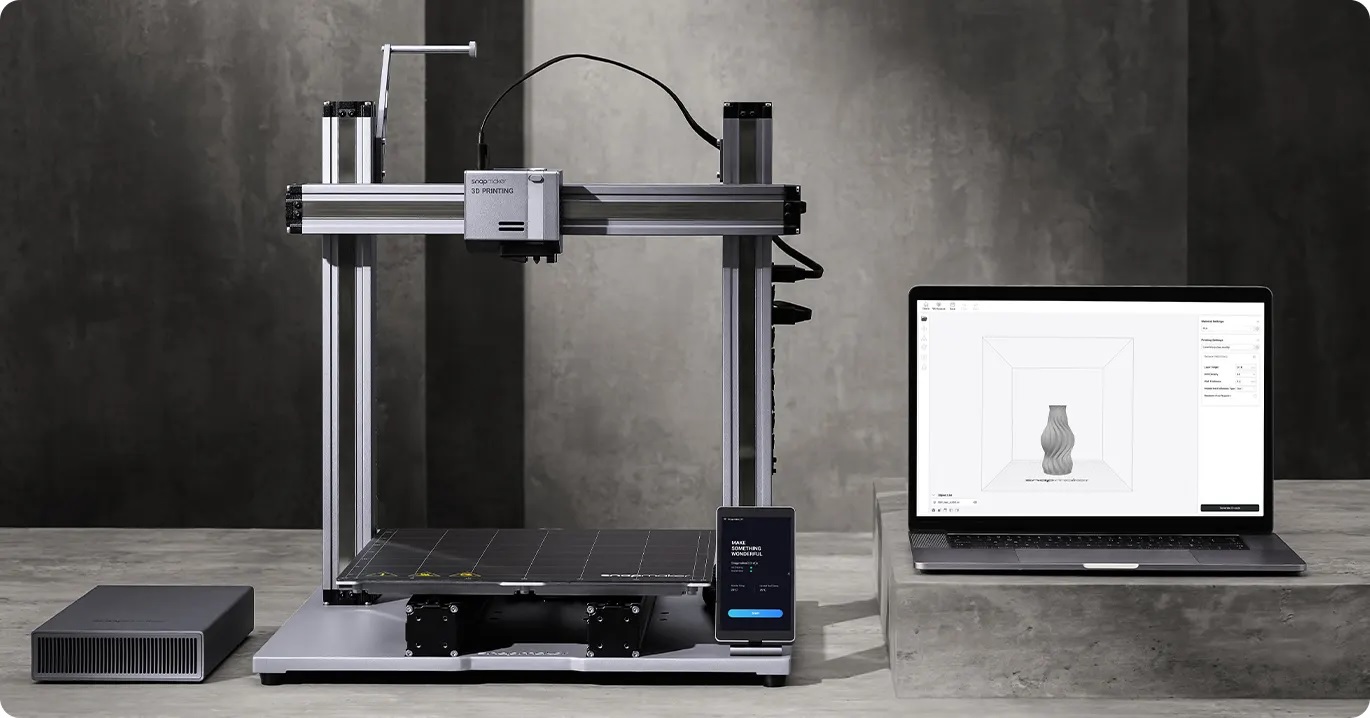

Snapmaker 2.0 3 in 1 Printer Model A250T, A350T

- Brands Snapmaker Code: V-SNAPMAKER-2-AT

A350T/A250T has several upgrades based on Snapmaker A350 and A250, offering a faster and quieter printing experience. The product includes everything you need to start your maker journey:

One-year warranty included

About A350T/A250T

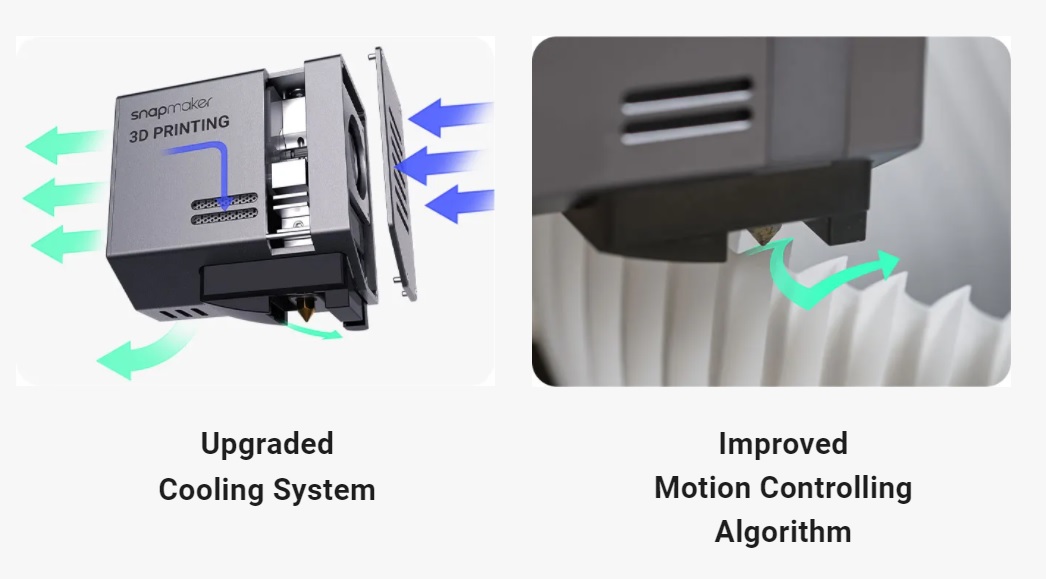

Thanks to the meaningful feedback from its supportive users, Snapmaker is able to keep perfecting the 2.0 series. And as a result, the latest iteration of Snapmaker A350/A250—A350T/A250T is equipped with a new 3D Printing Module, Linear Modules and Power Module. It boasts a better combination of print speed and quality, as well as a much quieter working environment.

Upgrades Based on User Feedback

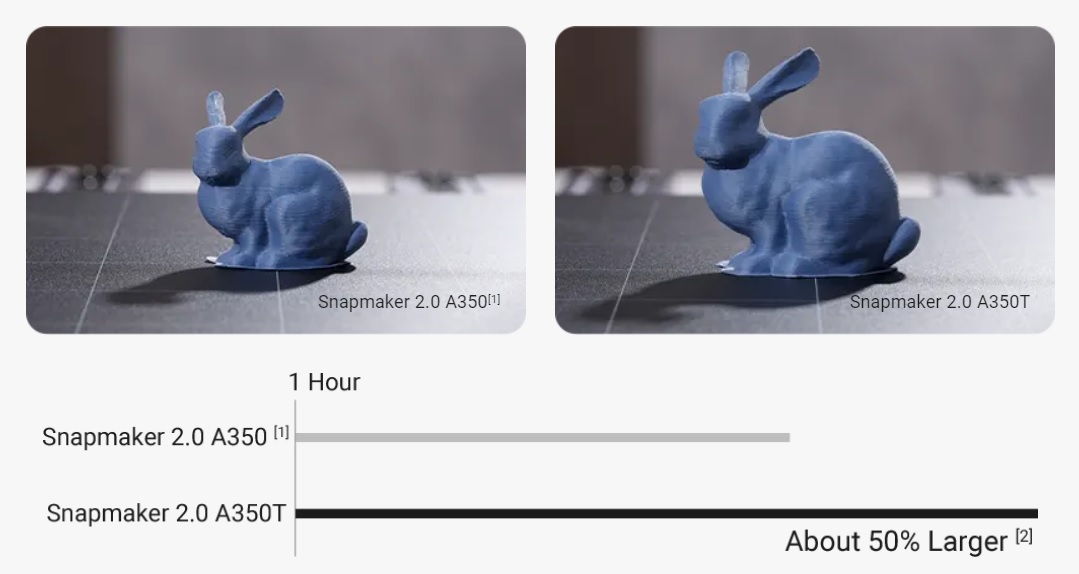

All for Faster Printing!

"Faster Printing" means that you can set higher speeds without compromising print quality. And along with that, in the subsequent update to Snapmaker Luban, the default work speed will be preset higher.

[1] The test result of A350 is from the previous version that has not been firmware upgraded for motion control algorithm improvement.

[2] The test result was obtained in Snapmaker laboratory, which may vary according to the testing conditions and product iteration, and is for reference only.

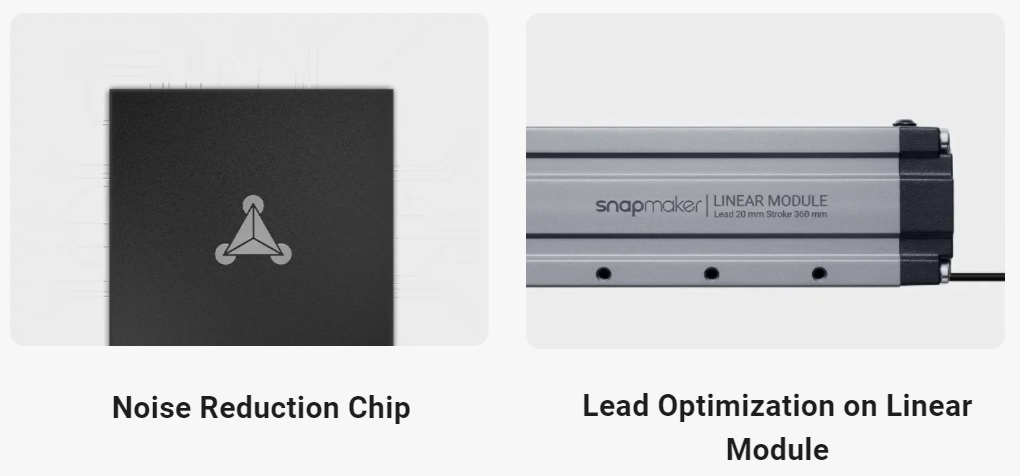

The Quieter the Better

During normal printing, the A350T/A250T has an average noise level of about 50 dB(A)—a typical home or office noise. Feel free to set the A350T/A250T in your living room or study and really spend time with it to check the print in real-time.

Power Module Improvement

The new Power Module uses a much quieter fan whose speed can be adjusted automatically according to the real-time temperature, realizing a noise level decrease of about 16 dB(A)[3], so that you can truly focus on your making.

[3] The test result was obtained in Snapmaker laboratory, which may vary according to the testing conditions and product iteration, and is for reference only.

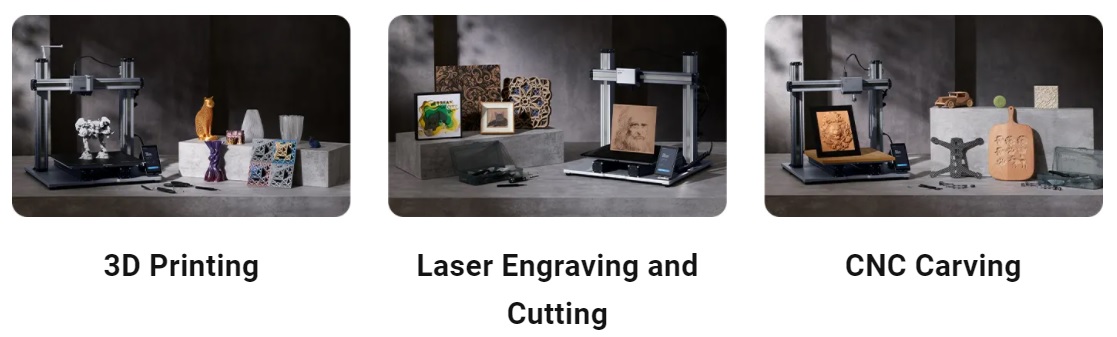

3-in-1

Snapmaker 2.0 Modular 3-in-1 3D Printer unlocks your full creative potential, from 3D printing to laser engraving, cutting, and CNC carving. Smarter, faster, larger, and more powerful than ever before, it is a new generation of 3-in-1 3D printers that comes with everything you need.

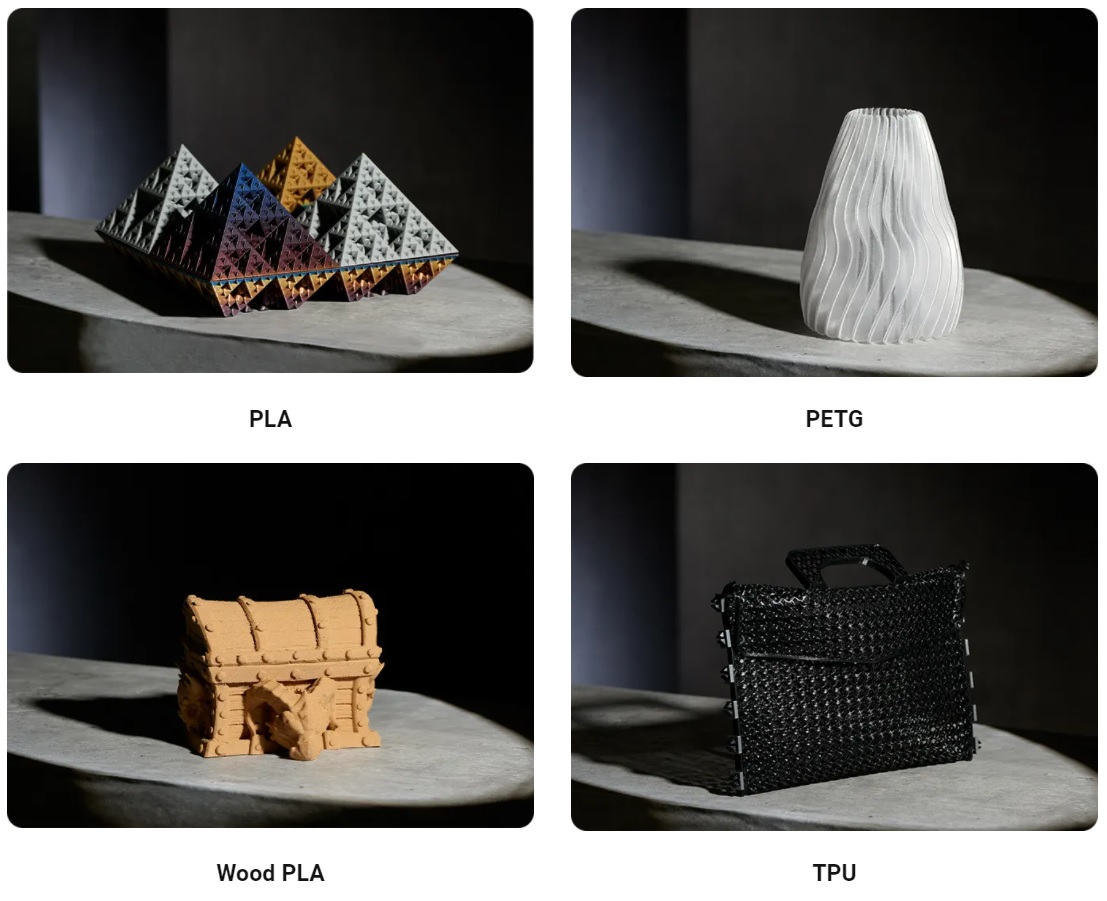

Dozens of Materials

3D Printing

You can print almost anything for your creative projects: from common applications to objects with specific mechanical properties, such as toughness, durability, and flexibility. A350T/A250T can do it all.

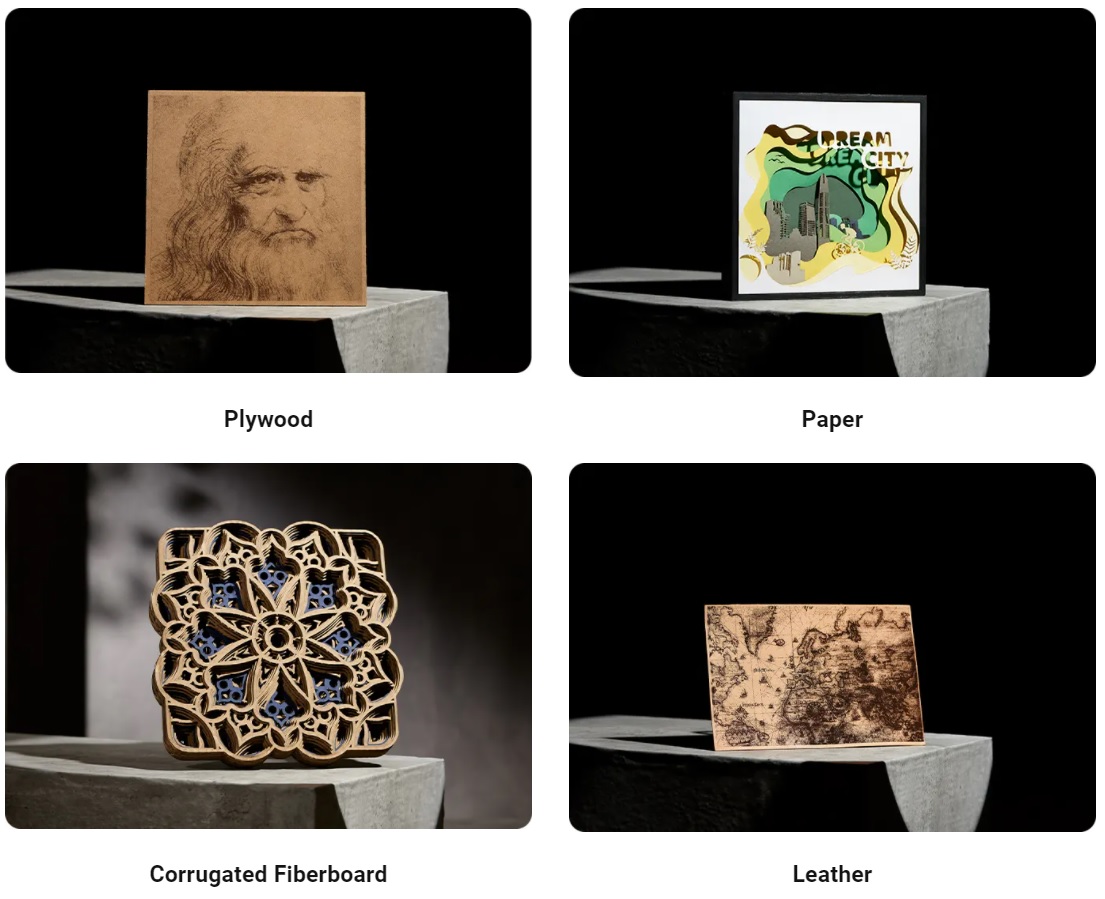

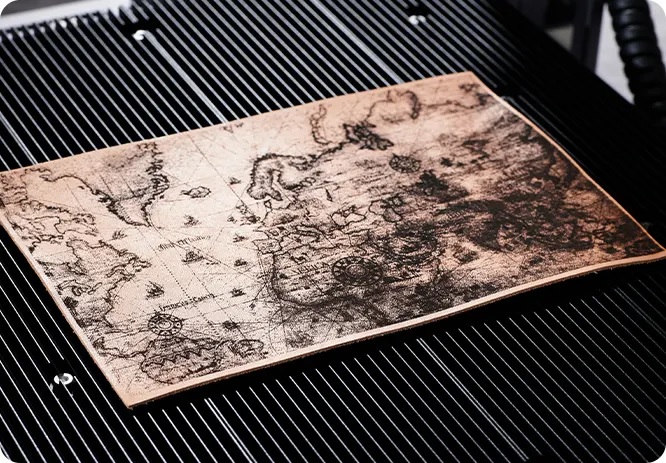

Laser Engraving and Cutting

A wide variety of materials you find in daily life are laser engravable or cuttable, including paper, plywood, leather, acrylic, cardboard, fabric, and even cookies and coconut shell!

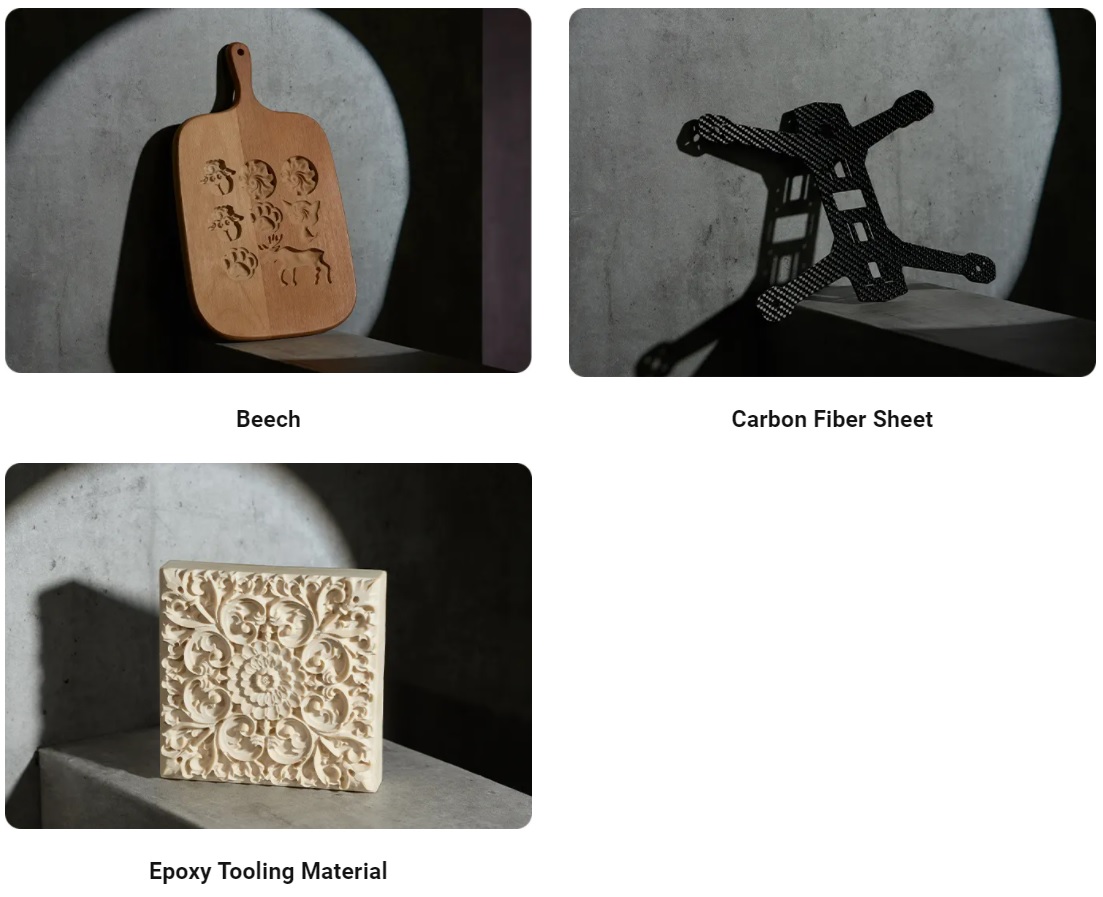

CNC Carving

CNC carving is ideal for precisely carving or cutting hard materials. With A350T/A250T, you are able to go beyond plastic or soft materials and choose among the following materials for your creative projects: hardwood, PCB, acrylic, POM, carbon fiber sheet, and many more.

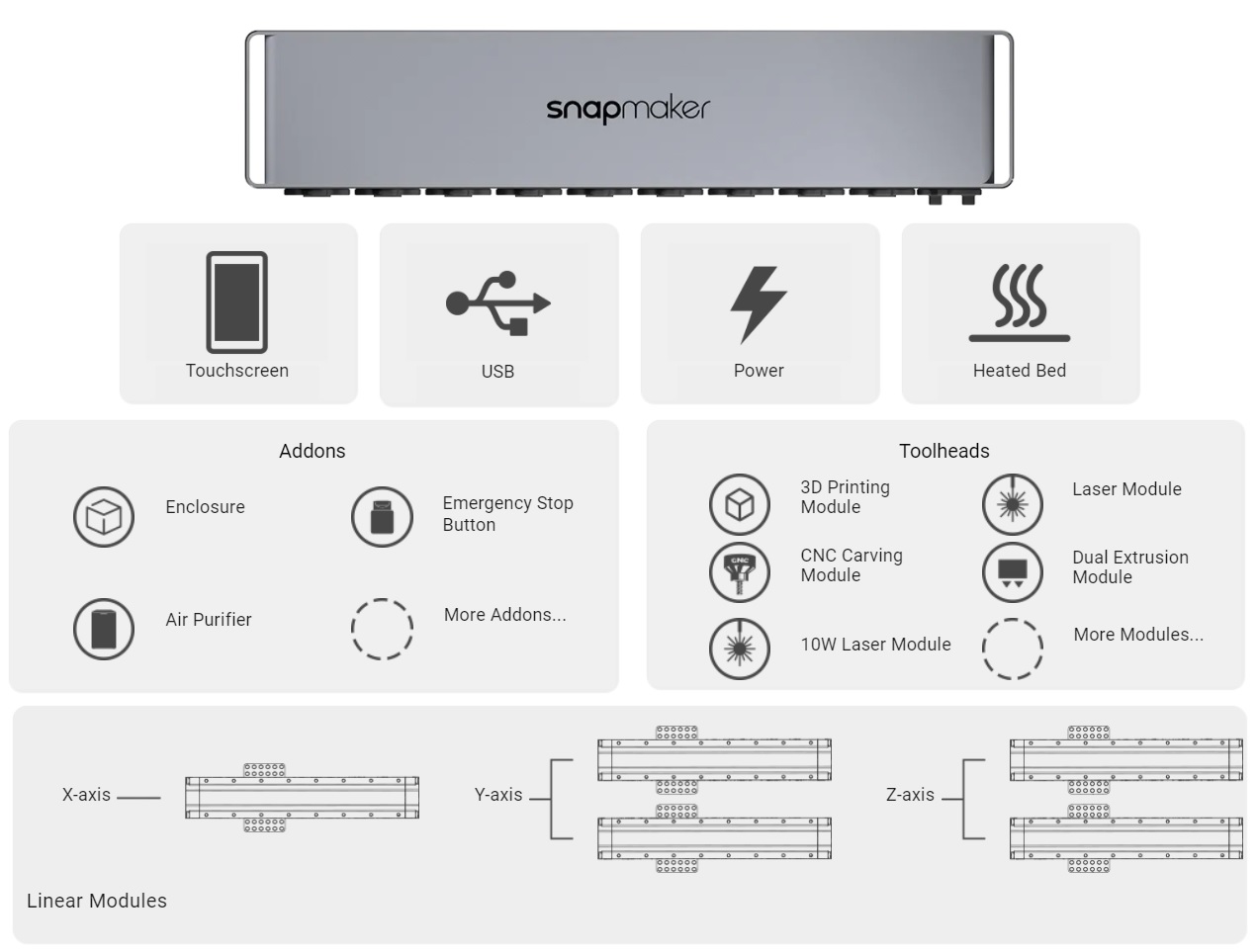

Modular Design

Quick Switching Among Functions

With the modular design, the tool heads and platforms work in their own ways but share the same mounting positions and methods. Changing functions on A350T/A250T is fast and easy.

Powerful Controller

One of the big reasons why A350T/A250T can support various modules and add-ons is that we have innovatively adopted the CAN (Controller Area Network) bus expansion. A special chip is built inside the controller to transmit all messages, which allows easy modification and inclusion of additional ports and controls in the future.

Modules & Addons

Thanks to its modularity, A350T/A250T can be personalized with a wide variety of modules and add-ons. For a greater level of applications, we have Enclosure, Rotary Module, Emergency Stop Button, CAN Hub, and Air Purifier available now. And there are more to come.

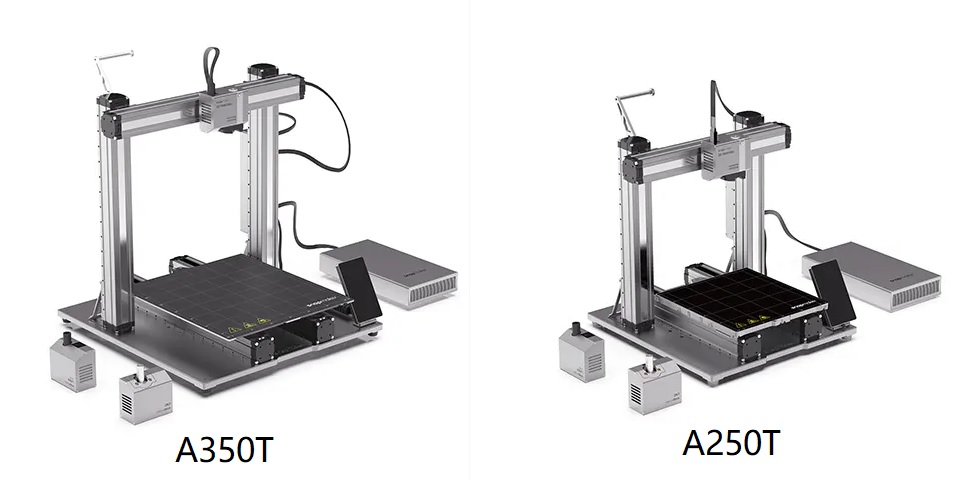

Large Work Area

A250T offers a large work area of 230 × 250 × 235 mm, and A350T expands it to 320 × 350 × 330 mm, where you can make large prototypes or multiple smaller objects in one go.

Ease of Use

Custom 3-in-1 Software: Snapmaker Luban

Snapmaker Luban is tailor-made for your Snapmaker machines. One single and powerful software for all your tasks. The software from version 4.0 comes with various user manuals and tutorial videos for you to start quickly. And with a plugin system and API, Snapmaker Luban even enables you to develop new features for your customized modules.

Power Loss Recovery

You don't have to worry about power outages anymore. A350T/A250T can automatically detect power loss, and then resumes exactly where it left off. You can recover any project and get perfect results all the time.

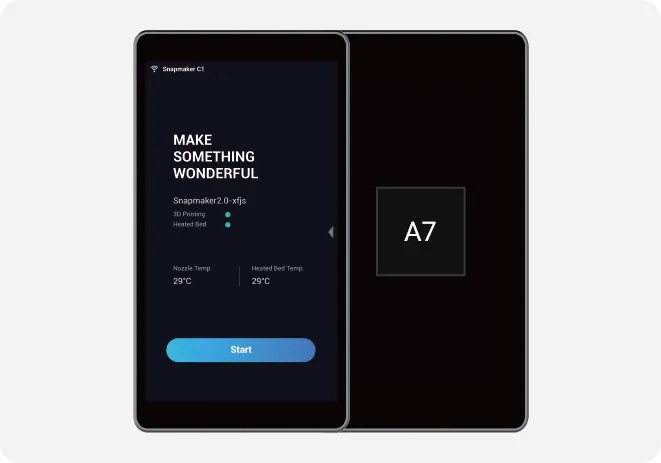

5-inch Touchscreen

A350T/A250T comes with an intelligent touchscreen that simplifies the workflow of your daily projects, letting you manage the most-used tasks directly from the touchscreen. Similar to a smartphone, this 5-inch (720 × 1280 pixels) movable touchscreen is equipped with a Quad-Core A7 CPU @1.1GHz, running under Android OS., providing a smooth and effortless user experience.

Wi-Fi Connectivity

With the Wi-Fi feature and the USB port, you can connect your machine to any configuration for your convenience. You can upload designs via Wi-Fi or USB flash drive and print with the touch of a button. In addition, you can update the firmware over Wi-Fi directly.

Easy To Assemble

If you build a thing, you know a thing. Assembling a working 3D printer sounds like a tough task, let alone assembling a laser cutter or a CNC router. Yet, we’re super confident that you’ll enjoy the process of assembling your own A350T/A250T, and find it simpler than you've ever thought.

3D Printing Highlights

Auto-levelling

To make bed levelling less tricky, we developed Auto Leveling. An induction sensor can probe the bed in a grid and apply mesh-based compensation that ensures you print on a level bed every time, all without complicated operations by yourself.

Filament Runout Recovery

Say no to unfinished prints or "air printing". Equipped with a filament runout sensor, the machine will remind you when the filament has run out. You can now print large objects without fear.

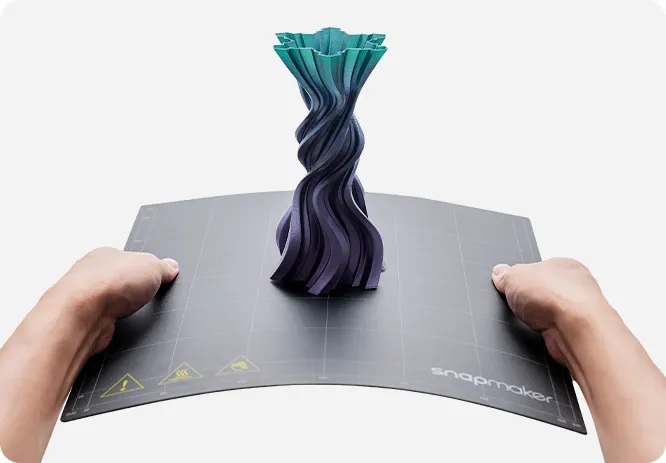

Flexible Print Sheet

Removing a print is now easier than ever. Just lift and flex the sheet, and your print will come right off. You can snap the print sheet back onto the magnetic heated bed in an instant.

Laser Engraving and Cutting Highlights

Built-in Camera

The built-in camera enables the Auto Focus and Camera Capture features, so that you will spend less time focusing on the laser, and can edit your design and position it exactly where you want it to be. What you see is what you get!

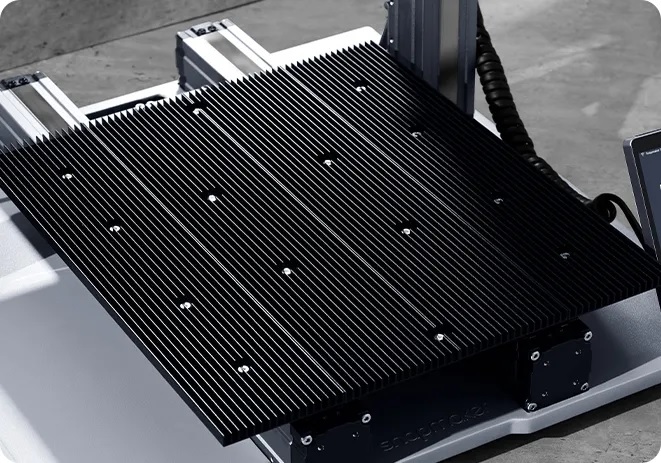

Aluminium Grid Table

The specially designed Aluminum Grid Table not only allows the smoke to be fully exhausted but also leaves enough space for laser penetration. It alleviates burn-in of the laser unit and excessive carbonization on the back of the material, enabling a more distinctively outlined laser cutting.

Highly Detailed Engraving

Using a semiconductor laser as its light source, the laser module is able to engrave with light dots as small as 0.2 mm, therefore making incredibly accurate images on various materials.

CNC Carving Highlights

ER11 Collet

The standard ER11 Collet guarantees a better concentricity that allows for a more stable CNC carving speed and larger step-down. It also supports over one hundred carving and cutting bits. The diameters of the bits range from 0.5 mm/0.02" to 6.35 mm/0.25".

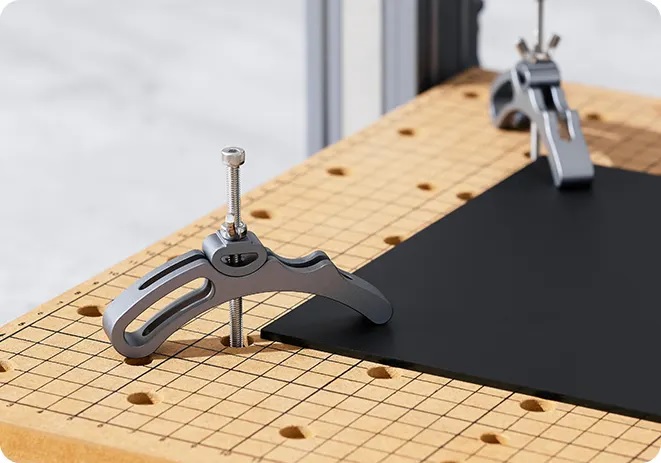

Custom MDF Platform and Clamp Sets

Each A350T/A250T comes with an MDF board and clamp sets. The board is removable and can protect other machine parts from damage, while the customized clamp sets offer a much easier and steadier fixation than before.

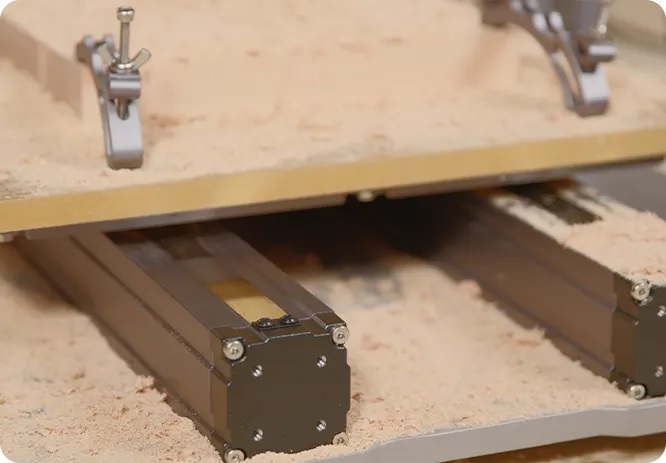

Dust Resistance

The leadscrew, driver chip, and precision parts of the linear modules are completely enclosed in the aluminium alloy housings, which eliminates the problem of dirt accumulation and ensures better durability.

Specifications

Size Comparison

Dimensions (W × D × H)

495 × 506 × 580 mm (A350T)

405 × 424 × 490 mm (A250T)

3D Printing

Work Area (W × D × H):

320 × 350 × 330 mm (A350T)

230 × 250 × 235 mm (A250T)

Max Heated Bed Temperature:

80℃ (A350T)

100℃ (A250T)

Laser Engraving and Cutting

Work Area (W × D):

320 × 350 mm (A350T)

230 × 250 mm (A250T)

CNC Carving

Work Area (W × D × H):

320 × 350 × 275 mm (A350T)

230 × 250 × 180 mm (A250T)

Tech Specs

Frame Material: Aluminium alloy

Data Transmission Methods: Wi-Fi, USB cable, USB flash drive

Touchscreen Specs: 5 in., Android OS, Quad-core 1.1 GHz ARM Cortex-A7

Supported File Types: .stl, .obj, more formats to be added

Supported OS: Windows, macOS, Linux

Rated Power: 320 W

3D Printing

Layer Resolution: 50–300 microns

Nozzle Diameter: 0.4 mm

Max Nozzle Temperature: 275°C

Supported Materials: PLA, ABS, PETG, TPU, wood-filled PLA, and more are being tested

Laser Engraving and Cutting

Camera: Built-in camera

Laser Power: 1600 mW

Wavelength: 450 nm

Safety Class: Class 4

Supported Materials: Wood, leather, plastic, fabric, paper, non-transparent acrylic, and more are being tested

CNC Carving

Shank Diameter: 0.5–6.35 mm

Spindle Speed: 6,000–12,000 RPM

Supported Materials: Wood, acrylic, PCB, carbon fibre sheet, jade, and more are being tested

Package Specs

Package Dimensions:

(W × D × H)

628 × 554× 312mm (A350T)

554× 554 × 312 mm (A250T)

Package Weight:

28.0kg (A350T)

24.0kg (A250T)